Continous Dewatering System

Goals:

Applications:

State of the art in mineral processing

step 1

Use thickener to separate water from slurry with 20% solid content. Gain up to 50% solid and recycle 20% of water

step 2

Transport the 50% slurry to tailing dam to give time and separate water from solids (0 to 40 microns)

step 3

Second recycling stage for the water in the tailing dam

Problems & disadvantages of the current systems

Tailing dams are harmful to the environment

risks of land slidingIt takes months to recycle the water whicch makes sycling time too high

The thickeners are extremely expensive and so is their maintanance

Slurry pumps and pipes are vulnerable to erosion. In fact internal parts of pumps need to be replaced every 20 days

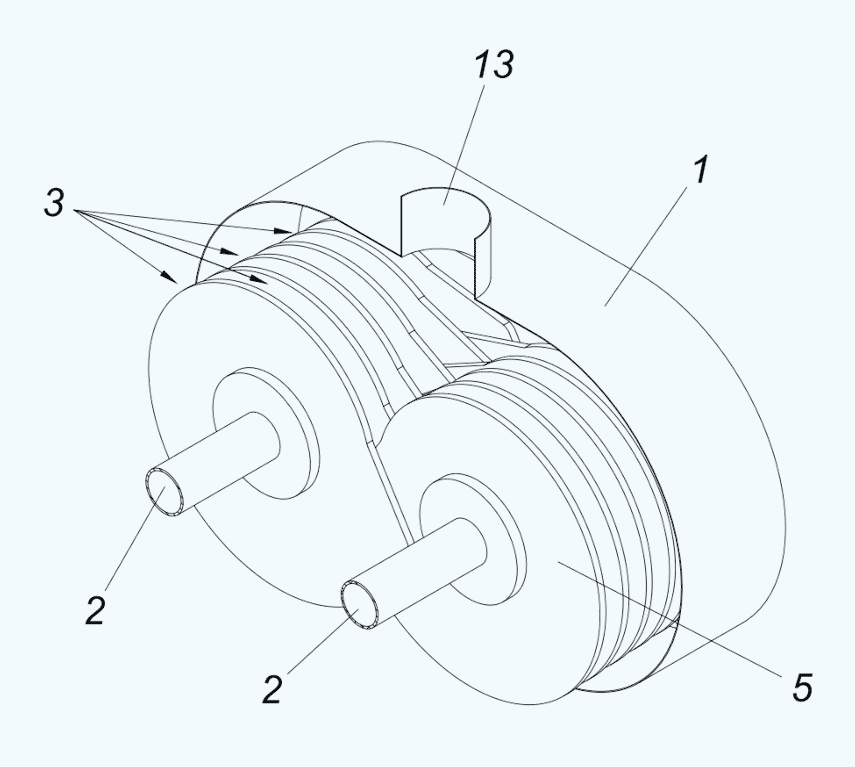

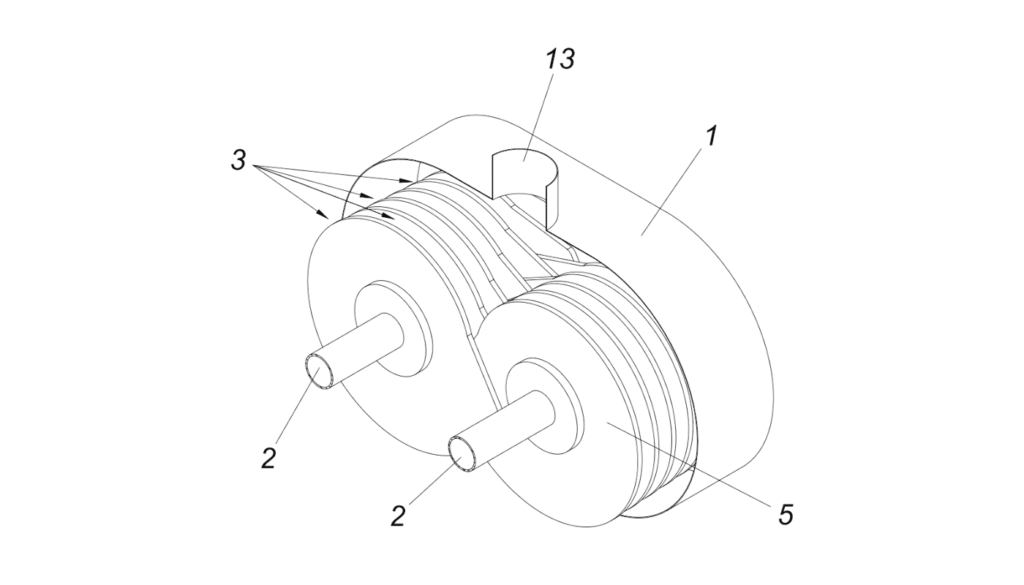

ETS Continous Dewatering System Concept

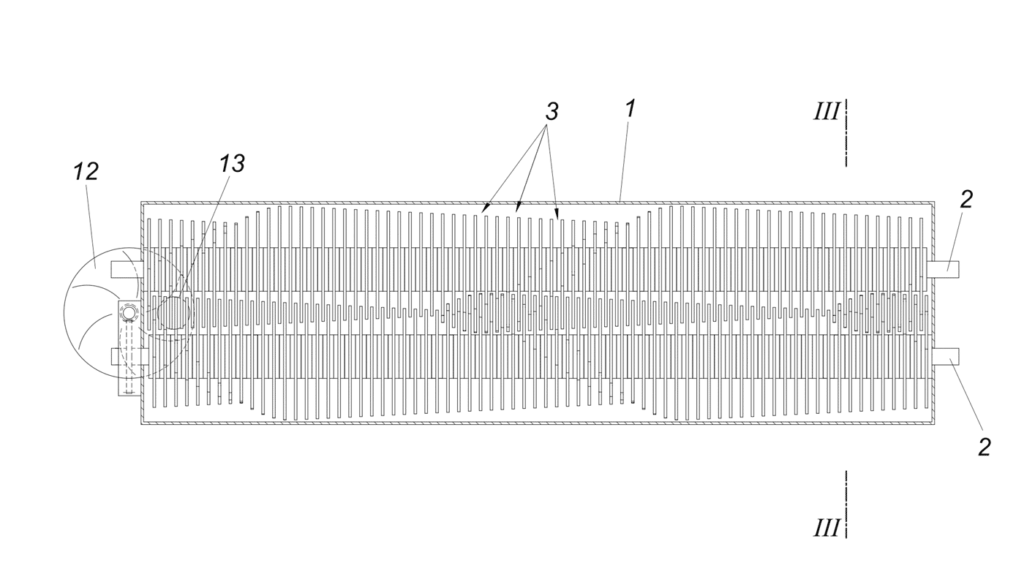

Each module is 6-12 meter

Casing plus two rotary screws

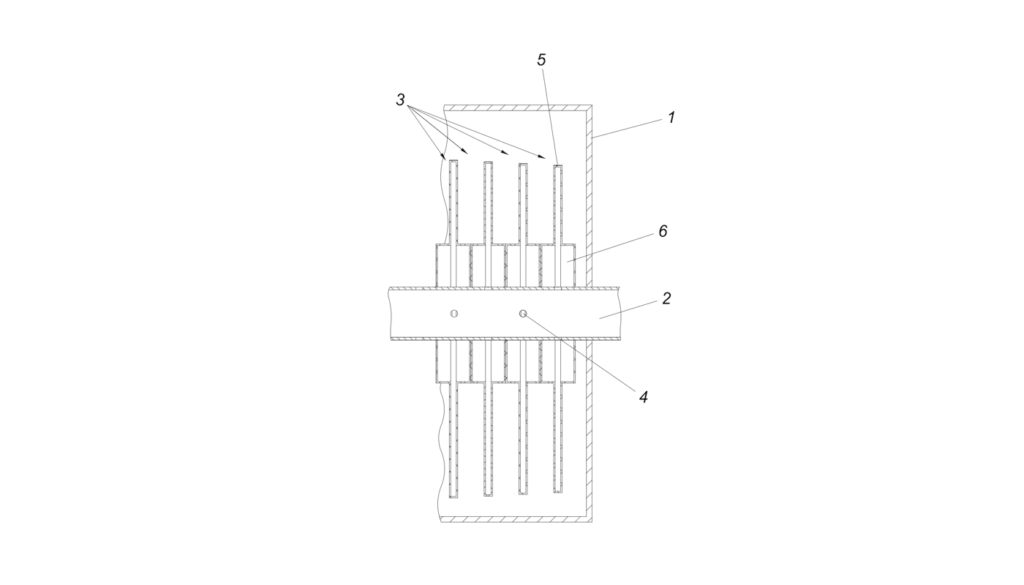

Each screw is a stacking of ceramic porose disks

Disks are hollow, shafts are hollow and disks are connected to the hollow shafts through holes

1

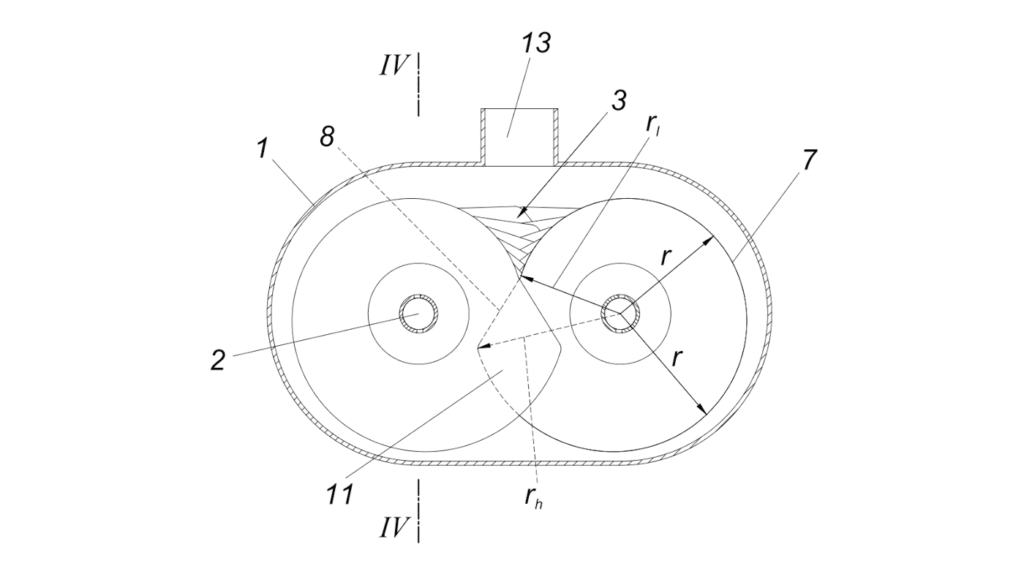

Slurry enters through no.13

2

Due to the high and low pressure waves, the water is get squeezed through ceramic to the hollow shafts

3

Water is collected through the shafts

4

The slurry moves forward with the help of rotation of screw

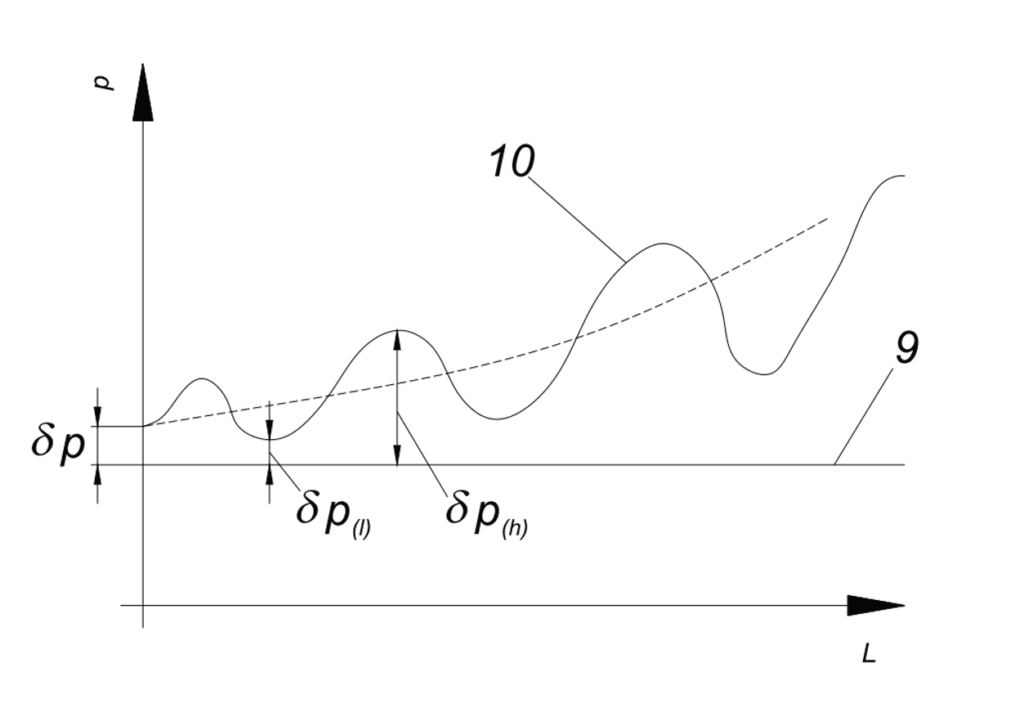

Intermittent or sinusoidal waves because of non-symmetric geometry of the disks

Line 9 shows the pressure on the water side inside the hollow shaft

L shows the distance along the module

Sinusoidal increase in pressure difference between slurry and water sides

Sinusoidal wave on slurry side is needed to separate the cake from the surface of the ceramic disks

The cake would stick and harden on the disks and the module will stall